1. About Zhongtian Yicheng

Hunan Zhongtian Yicheng Intelligent Technology Co., Ltd., located in Hunan, is a middle size manufacture of construction machinery, engineering machinery and robot. Annual revenue approached $30M. In 2021, Zhongtian Yicheng Company made progress in robot integration applications, achieving significant improvement in technology/processes. In 2023, the company invested significantly to upgrade its crane components products line to improve production efficiency and product quality.

2. Challenges

Facing an increasing competitive market environment, Zhongtian Yicheng has been exploring ways to improve production efficiency, reduce operational costs, and enhance core competitiveness. The customer kept manual method to manage complicated machinery manufacturing. The challenges are:

1). Manual Work Order Processing:

- Inefficient manual entry of work orders

- Higher risk of human error in data entry

- Time-consuming paperwork processes

- Lack of real-time order tracking capability

2). Production Order Management Problems:

- Offline management leading to delayed updates

- Lack of real-time visibility into production status

- Limited ability to respond to production changes quickly

3). Inventory Management Challenges:

- Inaccurate finished goods inventory counts

- Poor inventory tracking and control

- Risk of stockouts or excess inventory

- Difficulty in maintaining optimal stock levels

4). Operational Efficiency Issues:

- Low management efficiency overall

- Limited data integration across departments

- Slow decision-making processes

- Difficulty in implementing process improvements

3. Solution

The Zvalley intelligent manufacturing 5.0 solution utilizes the global infrastructure of AWS to provide SaaS-based services. The solution integrates advanced equipment, industrial robots, co-bot sensors and vision technologies, and provides different modules such as AIoT, MoM, MES, APS, PEM, and QMS to help customers build a visible, transparent, controllable, high-quality, and efficient smart factory and intelligent production line. The solution is built upon various AWS services including IoT, data and analytics, machine learning, and containers, leveraging the advantages of AWS's managed services and elastic scalability.

Zvalley implemented Manufacturing Operations Management (MoM) Systems for Zhongtian Yicheng to address the business challenges mentioned above. The MoM system transform shop floor data into actionable intelligence, enabling Zhongtian Yicheng to achieve unprecedented levels of efficiency, quality, and traceability. The key solutions elaborate as:

1) Upstream Delivery Collaboration: Integration with upstream SRM system to receive real-time purchase orders and delivery notes from customers, reducing communication costs and improving customer collaboration efficiency; real-time updates of customer order execution status based on receipt conditions, ensuring on-time delivery.

2) Intelligent Inventory Matching: One-click comparison of customer orders with current WIP and available inventory, intelligent guidance for planners in master production scheduling, reducing inventory stagnation.

3) Remnant Material Auto-matching: One-click generation of cutting requirements based on BOM, dynamic calculation of remnant inventory, prioritizing remnant material usage, dynamically reducing steel plate consumption.

4) Outsourcing Process Monitoring: Real-time monitoring of outsourcing progress through outbound and inbound tracking, supporting overdue reminders, preventing outsourcing stagnation risks.

5) Product management and details scheduling. Creates optimized, minute-by-minute job schedules for work centers and machines based on available capacity, materials, and labor.

4. Technical Architecture

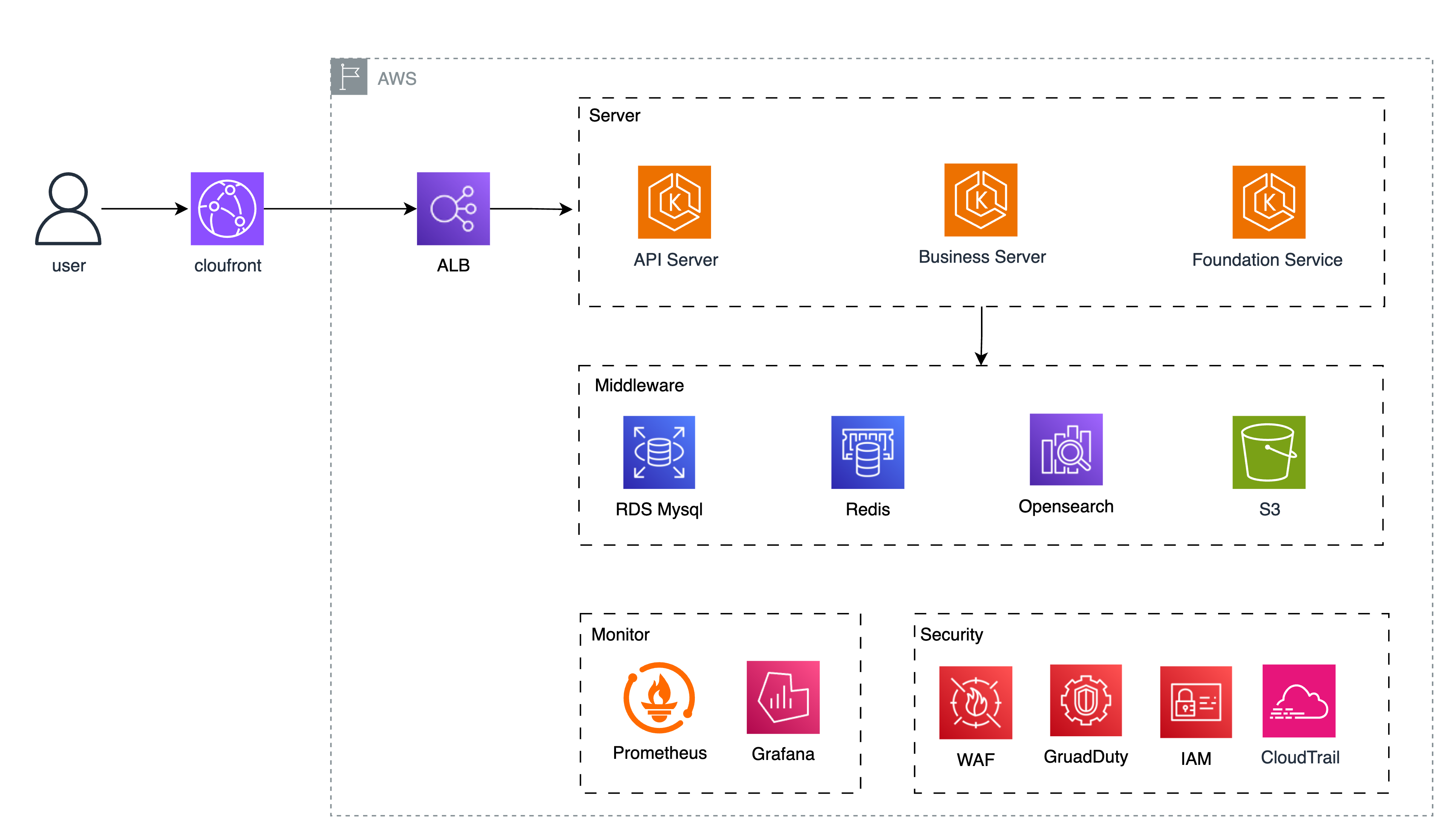

The platform's microservices are containerized using AWS EKS, ensuring high availability and elastic scaling. API Gateway provides authentication, authorization, traffic control, and request routing capabilities. Core business modules include R&D, planning, execution, equipment, quality, and warehouse management. The system utilizes AWS services for middleware including RDS MySQL, ElasticCache, MSK, OpenSearch, and S3, building a stable and reliable middleware service layer and data storage layer. The system implements monitoring through Prometheus and Grafana, along with AWS security services such as WAF, GuardDuty, IAM, and CloudTrail for comprehensive security protection and auditing.

5. Benefit and result

After the MoM system implementation, Zhongtian Yicheng achieved business results as:

1)Production Process Transparency: Shop floor routing guides production, unified information and material flow, real-time production data collection, enhancing visual management capabilities.

2)Precise Inventory Control: Detailed control by warehouse, storage area, zone, and location; real-time inventory visibility; establishment of line-side warehouses in each workshop to improve material flow efficiency; system-guided storage operations to enhance efficiency.

3)Production Performance Transparency: Real-time personal output visibility for workers, clear and transparent performance metrics, boosting worker productivity; automatic performance statistics compilation, efficient payroll processing support.

The summary of KPIs:

Cost Reduction: Dynamic remnant material control, reducing remnant costs by approximately 36%

On-time Delivery: Efficient upstream customer collaboration, delivery delay alerts, 15% reduction in delay rate.