1. About Dongzhou Electric

Hunan Dongzhou Electric Technology Co., Ltd. was established in 2005, which is an automation system integration solutions provider for new energy, rail transit, non-ferrous metallurgy, pharmaceutical industrials. The business focused on industrial automatic control system device manufacturing, metallurgical specialized equipment research and development, and rail transit equipment manufacturing.

2. Challenges

The company produces rail transit equipment and industrial automatic control device, the manufacturing operation and management efficiency are key business challenges, the specific challenges are:

1) Equipment Heterogeneity and Protocol Inconsistency

The factory contains a mix of new and old equipment using different communication protocols (such as Modbus, Profinet, S7 COMM, OPC UA, etc.) from various brands and models. The lack of unified data interface standards necessitates extensive development of adaptation programs when connecting to digital platforms, increasing integration complexity and costs.

2) Data Collection Scope and Quality Assurance

Required data collection spans equipment operating parameters, production process data, and energy consumption metrics. Legacy equipment often lacks data collection capabilities, requiring sensor retrofitting. Issues such as data jitter, noise interference, and mismatched sampling frequencies compromise data integrity and accuracy, undermining reliable analysis support.

3) Insufficient Edge Computing Capability and Data Transmission Pressure

The production site generates massive real-time data. Direct cloud transmission consumes substantial network bandwidth and risks data loss or latency due to network fluctuations. Current factory edge nodes generally lack data preprocessing, filtering, and analysis capabilities, preventing local data optimization and increasing cloud storage and processing burden.

4) Data Security and Privacy Protection Risks

Equipment data and production process information involve core business secrets. Data faces security risks during collection, transmission, storage, and usage, including leakage, tampering, and network attacks. Traditional IoT systems often lack comprehensive encryption mechanisms, access control, and security audit functions, failing to meet data security compliance requirements.

5) Disconnect Between Equipment Maintenance and Data Utilization

Despite achieving equipment data cloud integration, the lack of beverage production-specific data analysis models (such as equipment energy consumption systems, cost allocation, capacity optimization) prevents massive data from transforming into effective maintenance and production guidance. Equipment IoT and data collection remain at the visualization level without fully leveraging data's business management value.

3. Solution

The Zvalley intelligent manufacturing 5.0 solution utilizes the global infrastructure of AWS to provide SaaS-based services. The solution integrates advanced equipment, industrial robots, co-bot sensors and vision technologies, and provides different modules such as AIoT, MoM, MES, APS, PEM, and QMS to help customers build a visible, transparent, controllable, high-quality, and efficient smart factory and intelligent production line. The solution is built upon various AWS services including IoT, data and analytics, machine learning, and containers, leveraging the advantages of AWS's managed services and elastic scalability.

Zvalley implemented Industrial IoT platform for Dongzhou Electric to address the challenges mentioned above. This IIoT platform built on AWS infrastructure, enables factory-wide data collection, processing, and analysis for Dongzhou Electric's manufacturing operations.

1) Full-Scene Equipment Coverage, Weaving Intelligent Sensing Network:

Standardized unified data collection standard. Multi-protocol support (Modbus, Profinet, S7 COMM, OPC UA). Established a unified factory-wide energy allocation and loss analysis model, driving resource utilization efficiency up by 35%.

2) Standardized and Modular Design: This project initiated "Industrial Data Collection Standard System" at Dongzhou Electric, covering multi-dimensional data standards including equipment status, process indicators, energy consumption, and fault anomalies. The data collection system employs modular architecture design, supporting rapid adaptation to different production line equipment and seamless expansion to multiple factories.

3) Real-time Analytics and Reporting: Based on real-time data, built core indicator analysis models including Overall Equipment Effectiveness (OEE) and capacity load, automatically generating 20+ types of management reports including daily production reports and monthly energy consumption reports

4. Technical Architecture

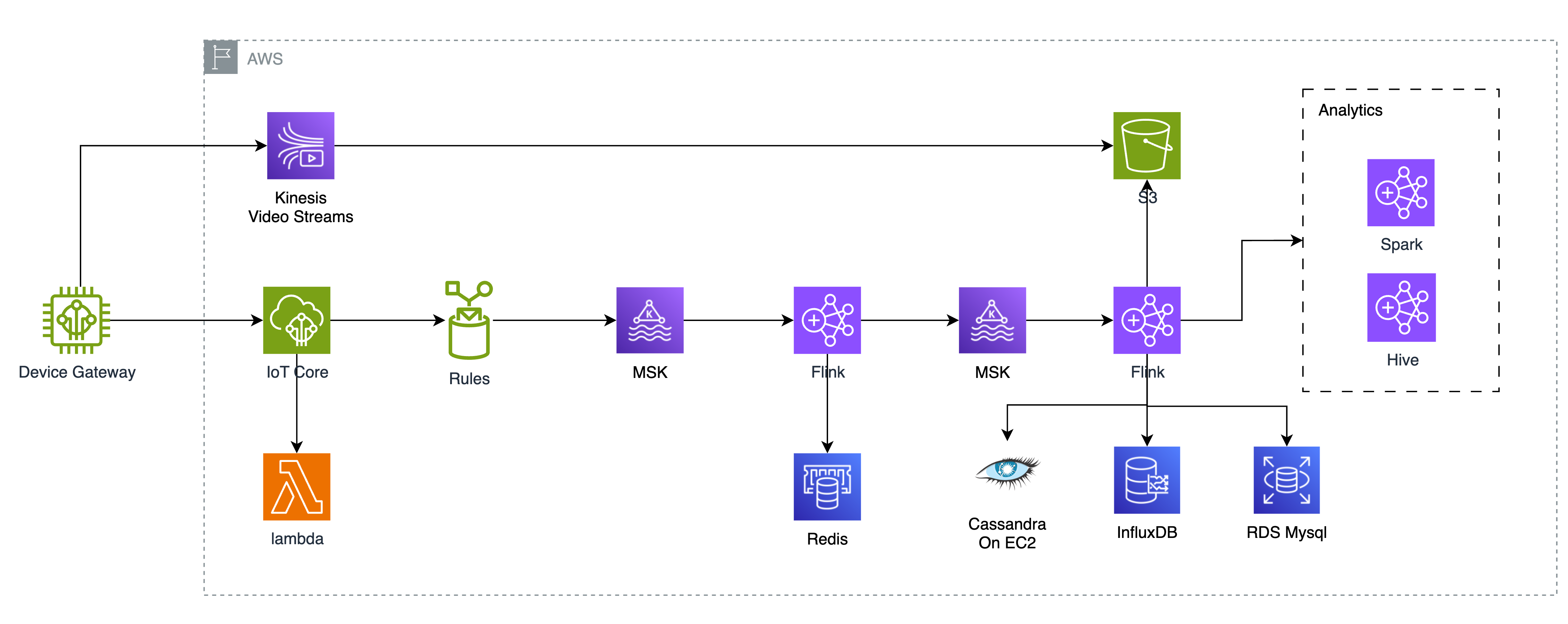

The overall platform architecture is built on AWS infrastructure. Equipment data connects through IoT Core, with data streams initially processed via AWS Lambda computing services, then processed in real-time through MSK (Amazon Kafka) and Flink. Processed data is stored in AWS S3 and further analyzed using Spark and Hive, with results stored in Cassandra, InfluxDB, and RDS MySQL databases. Redis is used for data caching, supporting real-time analysis and storage of large-scale IoT data processing scenarios.

- IoT Core for device connectivity

- Lambda for initial data processing

- MSK (Kafka) and Flink for real-time stream processing

- S3 for data storage

- Spark and Hive for big data analysis

- Multiple databases (Cassandra, InfluxDB, RDS MySQL) for different data types

- Redis for caching

5. Results and Benefits

After this IIoT platform was deployed, Dongzhou Electric established a digital production management system with "standardized collection, analytical models, and replicable business." They improved production management efficiency, through real-time energy data monitoring and intelligent allocation, dynamically optimizing water/electricity resource allocation, projected annual energy cost savings exceeding 3 million yuan. Standardized business models support cross-factory replication, enabling quick adaptation to new production lines or old-line renovation. After project implementation, the factory achieved a 130% increase in Overall Equipment Effectiveness (OEE), 50% improvement in production inspection efficiency, annual cost reduction exceeding 1 million yuan, and revenue increase of over 10 million yuan, driving comprehensive advancement in production execution efficiency and management effectiveness.

KPIs summary are:

Operational Improvements

- 130% increase in Overall Equipment Effectiveness (OEE)

- 50% improvement in production inspection efficiency

- 20% reduction in report compilation time

- 35% increase in resource utilization efficiency

Financial Benefits

- Annual cost savings exceeding 1 million yuan

- Revenue increase of over 10 million yuan

- Energy cost savings of 3 million yuan annually